The services of this website will be integrated into the D&DEPARTMENT Japan website.

As a result of this integration, all services offered on this site will conclude at 10:59 a.m. (JST) on July 30, 2025. Thank you for your support.

Starting July 30, we invite you to visit the D&DEPARTMENT Japan website to stay connected with us.

"ARCHIVES" preserves Japanese craftsmanship to the future.

It represents our original collection of bags made from unique textiles that showcase individuality through advanced techniques. This initiative aims to convey the brilliance of Japanese textiles and create new demand.

Movie: Canale in Ichinomiya City, Aichi Prefecture

The Bishu region of Ichinomiya City, Aichi Prefecture, has been a textile production area since old times. In the Meiji era (1868-1912), it was one of the first to focus on the wool industry in response to the trend toward Western-style clothing, becoming the largest wool producer in Japan. Founded in 1997, Canale weaves slowly at low speeds on over 50-year-old Schönherr looms, adding handicraft and finishing to create an exceptional textile.

We believe it is necessary to utilize dead stock and at the same time continue to create new fabrics while inheriting this production technology.

We have created a new coined term, "LIFESTOCK." It has the opposite meaning of dead stock. Items that remain in stock even though they can still be used as dead stock, or items that are in storage because they are no longer considered valuable because they are no longer in fashion. We collect these items and call them "LIFESTOCK." Our project has been in development since 2014, and aims to utilize their value and connect them to the next stage of manufacturing. We want to take that value and apply it to the next process.

In the course of this activity over the past 10 years, we have felt the crisis that the dead stock is gradually disappearing from Japan, and the number of weaving factories and craftsmen is decreasing year by year, so that the fabrics of those days can no longer be produced today.

Fabrics that are woven with high technology and take a long time to produce are more expensive. But in today's apparel industry, fast fashion, which can be mass-produced at low cost in a short period of time, has become mainstream. And there are no orders for beautiful fabrics full of individuality made with advanced techniques, so many factories are shutting down their machines and going out of business. Without creating demand, the Japanese textile industry itself will disappear. Aware of this situation, we are starting an activity called "ARCHIVES" to communicate the excellence of Japanese weaving techniques and create new demand.

Custom-Made Legacy Bags "ARCHIVES" Basic 020

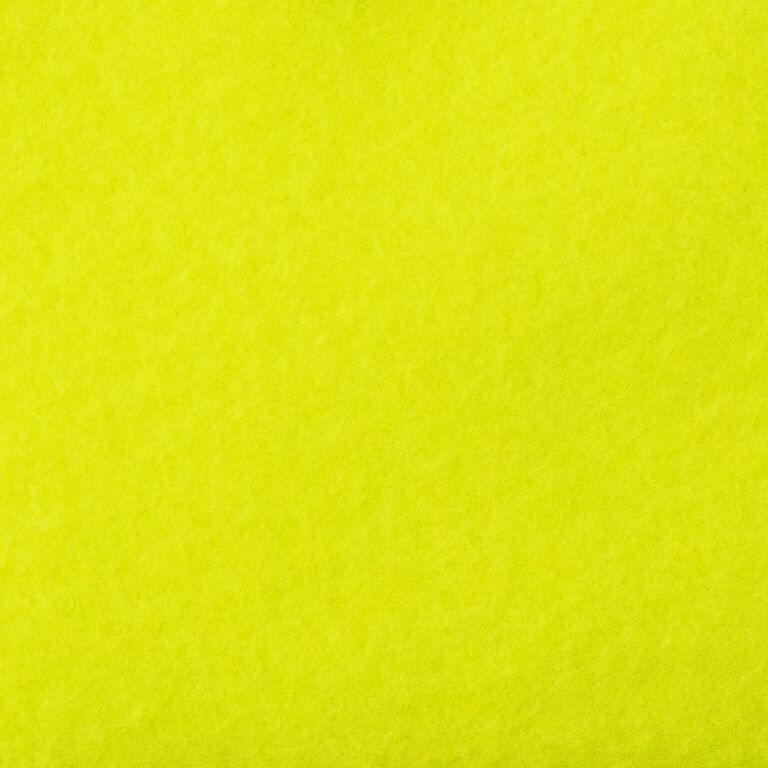

Incorporated in 1949, TOYOSYOKUFU is based in Chita, Aichi Prefecture, leveraging traditional techniques to manufacture fabrics for various purposes, from clothing to materials, using a variety of weaving machines. The fabric used for tennis balls adopts wool yarn as the weft and undergoes herringbone weaving followed by a gigging process, resulting in a soft texture. The distinctive feature includes a vibrant fluorescent yellow color, characteristic of tennis balls.

Manufacturing Area:

Chita, Aichi Prefecture

Manufacturer:

TOYOSYOKUFU

Technique:

Herringbone Weave, Gigging

Material:

Wool 90%, Nylon 9%, Cotton 1%

Custom-Made Legacy Bags "ARCHIVES" Basic 015

Founded in 1957 at the foot of Mt. Fuji, Miyashita Orimono specializes in dyeing yarn with spring water and creating finely woven, high-density fabrics. Primarily producing fabrics for wedding dresses and stage costumes, they use a unique technique that combines a smooth satin weave with high-speed needle punching, in which pin-holder-shaped needles pierce the fabric. This imparts a three-dimensional quality by pulling out the woof threads of the satin weave. The looped surface of the fabric creates a distinctive and charming impression with its unique depth.

Manufacturing Area:

Fujiyoshida City, Yamanashi Prefecture

Manufacturer:

Miyashita Orimono

Technique:

Satin Weave, Needle Punch

Material:

Polyester 100%

Custom-Made Legacy Bags "ARCHIVES" Basic 008

Founded in 1957 at the foot of Mt. Fuji, Miyashita Orimono specializes in dyeing yarn with spring water and creating finely woven, high-density fabrics. They primarily produce fabrics for wedding dresses and stage costumes. The Cut Jacquard is woven using Jacquard looms and then cut manually, resulting in an elegant three-dimensional effect produced by long, fringe-like threads that give it a distinctive presence.

Manufacturing Area:

Fujiyoshida City, Yamanashi Prefecture

Manufacturer:

Miyashita Orimono

Technique:

Cut Jacquard

Material:

Polyester 100%

Custom Made Legacy Bags "ARCHIVES" Basic 007

Textile designer, Kojima Hiyori learned artisanal skills from fabric regions across the country and uses them to maximize of the characteristics and attractiveness of each production area and expand her textile brand, terihaeru. Manufactured by TAENAKA PILE FABRICS in Wakayama Prefecture, an expert in weaving unique velvet materials. This fabric has the delicate unevenness of the fur and the vibrant coloring that only jacquard velvet can provide.

Manufacturing Area:

Kōyaguchi, Wakayama Prefecture

Manufacturer:

TAENAKA PILE FABRICS Co.,Ltd.

Design:

Kojima Hiyori (terihaeru)

Technique:

Jacquard Velvet

Material:

Fabric base (Cotton 53%, Linen 47%), Pile (Acrylic 100%)

Custom-Made Legacy Bags "ARCHIVES" Basic 003

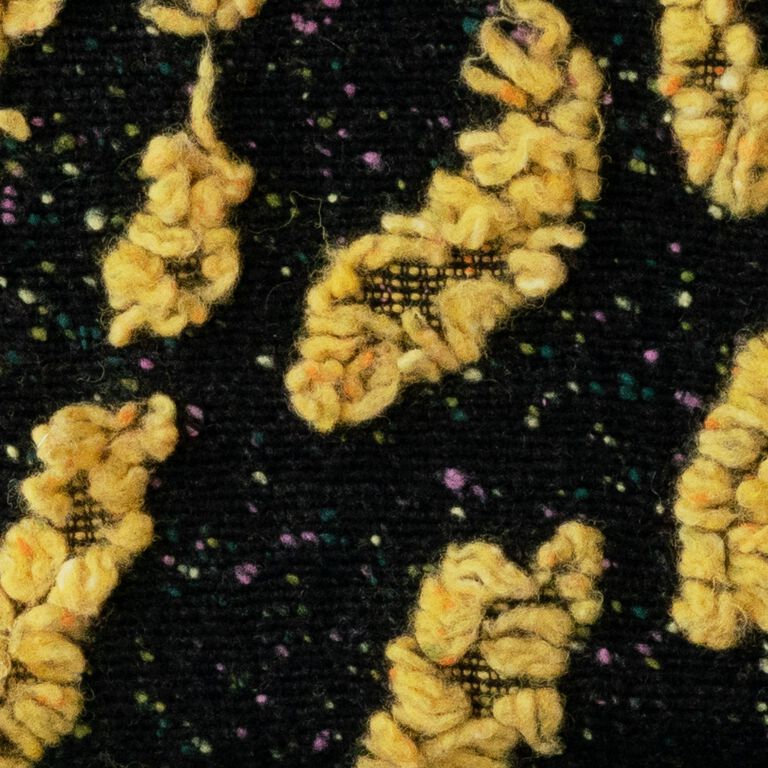

Founded in 1997 by Akira Adachi in Ichinomiya City, Aichi Prefecture, Canale is a textile planning company. They create distinctive textiles through manual work and processing. In this fabric, wool yarns are used as weft yarns, and the yarns are skipped without being woven in, and then the skipped wool yarns are cut by hand. Through washing and felting, the pattern emerges, resulting in a fabric with a unique design.

Manufacturing Area:

Ichinomiya, Aichi Prefecture

Manufacturer:

Kozuka Keori Co.,Ltd.

Design:

Canale

Technique:

Cut Jacquard

Material:

Cotton 70%, Wool 28%, Nylon 2%

Compared to ten years ago, there seem to be more government initiatives and younger people promoting the revitalization of local industries. However, the current situation remains challenging. In the midst of this, there are producers who are tirelessly creating "specialty fabrics" with distinctive features that attract global attention, even though their scale may be small. While visiting these regions, we discovered "specialty fabrics" that couldn't be included in the "LIFESTOCK" project due to budget constraints, and we feel a strong desire to preserve these fabrics, as they may one day become unavailable. We want to share the existence of these remarkable fabrics with many people and hope that they become a part of everyday life. By offering them as products, we believe it could provide an opportunity for people to order the fabric, enabling the producers to continue their work. With this in mind, we have created the "ARCHIVES" series, and hope that you will enjoy these custom-made legacy bags, each made from their uniquely rich fabric, like individual treasures. (Text: Hisae Shigematsu / D&DEPARTMENT Fashion Coordinator)

You may select your bag from five distinct types of fabric. Please keep in mind that you can't customize the dimensions or design. The colors of photographs may vary depending on the shooting conditions, lighting, viewing environment (desktop monitor or smartphone screen), etc. Please note that there may be slight differences in color and texture between the photo and the actual item.